As an acrylic bathtub manufacturer at Salvere, operating from Vietnam, I've seen firsthand how quickly global trade policies can shift. For bathtub brands, fluctuating tariffs are more than just a line item change; they disrupt established supply chains, inflate costs, and threaten market competitiveness. It's a problem that demands strategic thinking and proactive solutions, which is exactly what we help our partners achieve.

To keep a bathtub supply chain stable under tariff pressure, brands must adopt a multi-faceted approach, starting with understanding global trade dynamics. Key strategies include diversifying manufacturing across multiple countries to reduce reliance on single-origin production, partnering with flexible OEM/ODM manufacturers capable of agile responses, strategically leveraging tariff-free zones and trade agreements, and optimizing inventory management for resilience. Ultimately, choosing a manufacturing base with long-term stability and favorable trade policies is paramount for mitigating tariff-related risks and ensuring continuous product flow.

Let's explore how to navigate these turbulent waters and build a more resilient bathtub supply chain.

Why Global Tariff Changes Disrupt Bathtub Brands?

It is more than just taxes.

Global tariff changes disrupt bathtub brands profoundly because they directly inflate import costs, diminishing profit margins or forcing price increases that reduce competitiveness. Beyond immediate financial impact, tariffs complicate logistics, foster supply chain uncertainty, and can necessitate expensive, time-consuming reconfigurations of manufacturing and sourcing strategies, straining relationships with existing partners and requiring significant operational adjustments.

Tariffs, which are essentially taxes on imported goods, can seem like a simple concept, but their ripple effect throughout a supply chain is complex and far-reaching.

- Increased Costs: The most obvious impact. If a tariff is imposed on bathtubs from a specific country, the importer (your brand) pays this tax. This either eats into your profit margins or forces you to raise prices, making your product less competitive.

- Uncertainty and Risk: Tariff policies can change rapidly, often driven by geopolitical events. This unpredictability makes long-term planning difficult for brands. Investments in certain regions can become risky overnight if tariffs suddenly make them uneconomical.

- Supply Chain Reconfiguration: Brands might need to divert orders from a tariff-affected country to another, which is not an overnight process. This involves identifying new suppliers, qualifying factories, setting up new logistics, and sometimes even re-tooling. This transition is costly and time-consuming.

- Impact on Relationships: Existing relationships with suppliers in affected regions can become strained if order volumes drop due to tariffs.

- Product Availability: Supply chain disruptions due to tariffs can lead to delays, stock-outs, and an inability to meet customer demand, damaging brand reputation.

Understanding these disruptions is the first step toward building resilience.

Common Supply Chain Risks Faced by Bathroom Product Companies

Navigating complexity for bathtubs.

Bathroom product companies, especially in the bathtub sector, face common supply chain risks including material sourcing volatility, geopolitical instability, and logistics bottlenecks, all exacerbated by single-country dependency. Quality control issues can arise from fragmented production, while demand fluctuations and economic downturns directly impact inventory and sales. Furthermore, intellectual property theft and insufficient regulatory compliance pose significant operational and legal threats, making a diversified and robust supply chain strategy essential for sustained business continuity.

Beyond tariffs, bathtub and other bathroom product companies must contend with a range of supply chain vulnerabilities.

- Single-Source Dependency: Relying on one factory or one country for production. While efficient when stable, it creates extreme vulnerability to any disruption in that region (tariffs, natural disasters, political instability, labor issues).

- Quality Control Issues: Especially when dealing with complex products like bathtubs, maintaining consistent quality across different suppliers or new production lines can be challenging.

- Logistics Bottlenecks: Port congestion, shipping container shortages, and rising freight costs can cause significant delays and added expenses.

- Geopolitical Instability: Trade wars, political unrest, or strained international relations can lead to sudden policy changes and supply interruptions.

- Lack of Transparency: Not having clear visibility into the entire supply chain, including sub-suppliers, makes it hard to identify and mitigate risks proactively.

- Intellectual Property (IP) Theft: Especially in certain regions, protecting proprietary designs and manufacturing processes can be an ongoing concern.

- Regulatory Compliance: Ensuring products meet safety, environmental, and quality standards in diverse markets (e.g., North America, Europe, Australia) requires constant vigilance and can lead to costly delays if overlooked.

Addressing these risks proactively is crucial for long-term supply chain health.

How Multi-Country Production Can Reduce Tariff Risk

Don't put all your eggs in one basket.

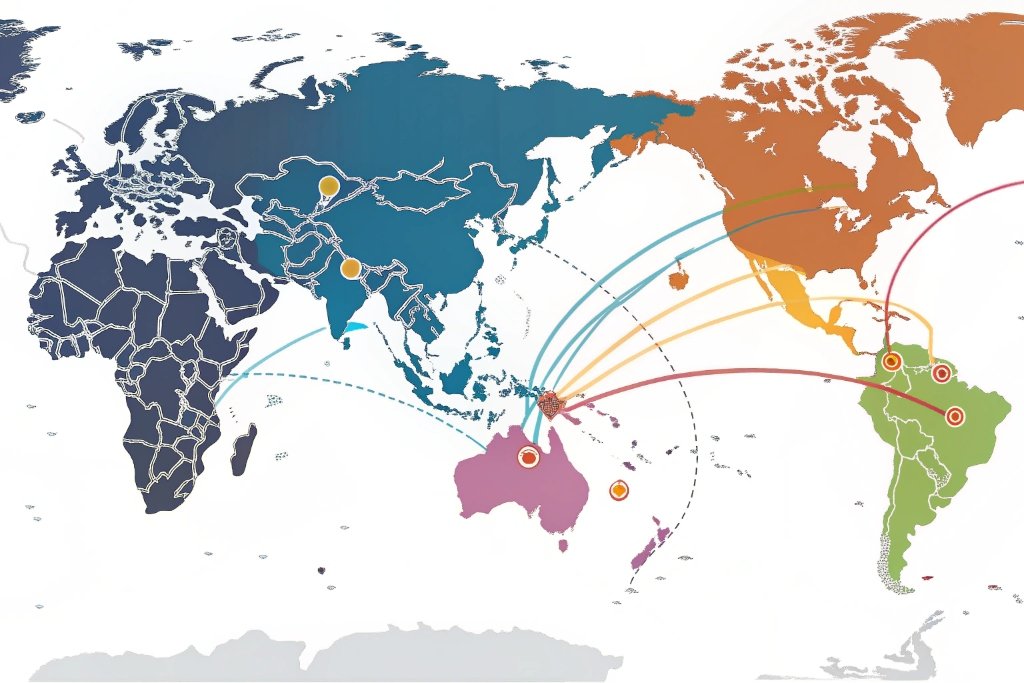

Multi-country production significantly reduces tariff risk for bathtub brands by enabling flexible sourcing and mitigating over-reliance on any single nation. By establishing manufacturing bases in diverse regions, brands can pivot production volumes quickly in response to new tariffs, leveraging favorable trade agreements and avoiding punitive duties. This strategy ensures supply continuity, stabilizes costs, and enhances market access by maintaining competitive pricing across various geopolitical landscapes.

This is one of the most effective strategies we advocate for at Salvere, and it's precisely why our Vietnam operation exists.

- Geographic Diversification: By having manufacturing facilities in multiple countries, you spread your risk. If tariffs are imposed on goods from Country A, you can shift some or all production to Country B, which might have more favorable trade terms.

- Hedging Against Policy Changes: It creates a natural hedge against unpredictable government policies. You're not beholden to the whims of a single trade relationship.

- Optimized Market Access: Each country might have different bilateral or multilateral trade agreements, allowing you to optimize production for specific markets to minimize import duties for those regions. For instance, goods from Vietnam might enter the US or EU with lower tariffs than those from China, depending on product classification and trade agreements.

- Enhanced Supply Chain Resilience: Beyond tariffs, having multiple production sites makes your supply chain more robust against other disruptions like natural disasters, pandemics, or labor disputes in a single region.

- Competitive Advantage: Brands with diversified supply chains can often maintain more stable pricing and supply to their customers, gaining an edge over competitors heavily reliant on single-country sourcing.

Multi-country production is not just a reactive measure; it's a proactive strategy for stability.

The Role of Flexible OEM/ODM Manufacturing Partners

Your adaptable problem-solvers.

Flexible OEM/ODM manufacturing partners are vital for bathtub companies navigate tariff pressures by offering agile production shifts, rapid re-sourcing capabilities, and expertise in diverse regulatory environments. They absorb the complexity of multi-country operations, quickly adapting to new trade policies and enabling brands to maintain supply continuity without extensive direct investment in foreign facilities. This partnership model allows brands to focus on core competencies while leveraging the manufacturer's adaptability to minimize tariff-related costs and disruptions.

This is where a partner like Salvere truly shines. We, as an OEM/ODM acrylic bathtub manufacturer, help brands execute these multi-country strategies without the brand having to build and manage multiple factories themselves.

- Agility and Speed: Flexible OEM/ODM partners can quickly reallocate resources and production lines, adapting to changes in tariff landscapes much faster than a brand could by setting up new operations from scratch.

- Expertise in Local Regulations and Trade Agreements: Good OEM/ODM partners are deeply familiar with the trade policies, compliance standards, and logistics in their respective manufacturing locations, ensuring smooth product flow and customs clearance.

- Reduced Capital Investment for Brands: Brands don't need to invest heavily in foreign infrastructure. They leverage the existing facilities, skilled labor, and supply networks of their OEM/ODM partner.

- Customization and Adaptation: Partners can adapt product specifications to suit different market requirements or incorporate design modifications necessary for specific manufacturing processes in new regions.

- Supply Chain Visibility and Management: Reputable OEM/ODM partners offer transparency into their supply chain, helping brands monitor production, quality, and shipping, even across varied geographical locations.

Choosing a flexible and strategically located OEM/ODM partner is key to minimizing tariff-related headaches.

Strategies for Leveraging Tariff-Free Zones and Trade Agreements

Smart sourcing for savings.

Leveraging tariff-free zones and trade agreements is a critical strategy for bathtub brands to mitigate import duty pressures, by strategically directing production to countries participating in preferential trade blocs. This involves meticulously analyzing country-of-origin rules, optimizing manufacturing processes to meet specific content requirements, and collaborating closely with suppliers who possess a deep understanding of international trade policies, thereby securing advantageous tariff rates and enhancing product competitiveness in key markets.

This is all about understanding the global trade landscape and using it to your advantage.

- Identify Relevant Free Trade Agreements (FTAs): Research which FTAs exist between your manufacturing countries and your target sales markets. For example, the US has FTAs with many countries, as does the EU with its network of agreements.

- Understand Rules of Origin: This is crucial. To qualify for reduced or zero tariffs under an FTA, your product must meet specific "rules of origin." This often means a certain percentage of the component parts or the entire manufacturing process must occur within the signatory countries.

- Strategic Sourcing Location: Choose manufacturing partners in countries that are part of relevant FTAs. For example, if you sell primarily to the US and EU, a manufacturer in Vietnam (like Salvere) might offer tariff advantages under various agreements.

- Collaborate with Expert OEM/ODM Partners: Your manufacturing partner should have a clear understanding of these agreements and rules of origin to ensure your product qualifies for the best possible tariff rates. They can guide on material sourcing and manufacturing processes required.

- Documentation is Key: Properly documenting the origin of materials and the manufacturing process is essential to prove compliance and avoid tariffs during

This strategy requires careful planning and expert knowledge of international trade.

Planning for Better Inventory and Shorter Lead Times

Efficiency in a dynamic world.

Planning for better inventory and shorter lead times is essential for bathtub companies facing tariff pressures, as it minimizes capital tied up in potentially high-tariff goods and enables rapid adaptation to market shifts. By optimizing production schedules, implementing lean manufacturing principles, and strategically leveraging multi-country sourcing, brands can reduce excess stock, accelerate product delivery, and mitigate the financial impact of sudden tariff changes by reducing exposure to long inventory cycles with uncertain duty rates.

Agility is key when tariffs are unpredictable. Smarter inventory and shorter lead times contribute directly to this.

- Reduce Reliance on "Just-in-Case" Inventory: Holding vast amounts of inventory from potentially tariff-affected regions ties up capital and exposes you to higher duties if tariffs change while goods are in transit or storage.

- Implement Just-in-Time (JIT) Principles: While challenging for overseas manufacturing, working with flexible partners to minimize lead times allows you to respond more quickly to demand shifts and tariff changes, reducing the need for large buffer stocks.

- Forecast Demand Accurately: Better forecasting means producing what you need, when you need it, minimizing excess inventory.

- Diversified Sourcing for Critical Components: If primary components for your bathtubs come from a tariff-prone region, source secondary components from other regions. This limits the impact on the final product if one component source becomes too expensive.

- Utilize Flexible Production Capabilities: A manufacturer that can quickly scale up or down production, or switch between product lines, helps you adjust to market demands without accumulating stale inventory.

Shorter lead times and optimized inventory management reduce financial risk and increase responsiveness.

How to Choose a Reliable Manufacturing Base for Long-Term Stability?

Location, reputation, and foresight.

Choosing a reliable manufacturing base for long-term supply chain stability requires evaluating geopolitical risk, existing trade relationships, and the quality of local infrastructure. Prioritize regions with diversified economies, transparent regulatory frameworks, and a skilled labor pool, while also assessing the manufacturer's track record, technological capabilities, and commitment to global compliance standards.

A good example is Vietnam, which has become a strong choice for many brands looking to move part of their production outside of traditional hubs.

At Salvere, we built our acrylic bathtub factory in Ho Chi Minh City with long-term resilience in mind. The facility focuses only on one product category—acrylic bathtubs—and integrates 14 standardized production steps, helping partners maintain quality, efficiency, and lead time control.

With Vietnam’s trade advantages and stable infrastructure, this setup offers a practical solution for brands aiming to reduce tariff exposure and diversify their supply chain without compromising product consistency.

Key considerations include:

-

Geopolitical Stability and Trade Policies

Look for countries with stable governments and a proactive approach to international trade agreements. Assess their relationships with your target markets. -

Economic Outlook and Labor Force

A growing economy often indicates a stable and improving infrastructure. A skilled and productive labor force is essential for consistent quality and scalable production. -

Infrastructure

Evaluate port capacity, road networks, and energy supply. Reliable logistics are non-negotiable. -

Regulatory Environment and Compliance

Choose countries with transparent, consistent regulatory frameworks. Ensure your manufacturer meets international compliance standards for your target regions. -

Manufacturer’s Expertise and Investment Capacity

Look for manufacturers that specialize in your product category and continue to invest in advanced technology and process improvements.

Conclusion

Navigating global trade complexities—especially under rising tariff pressure—demands more than short-term solutions. For bathtub brands, long-term success depends on building a resilient and adaptable supply chain.

By embracing multi-country manufacturing strategies, collaborating with flexible OEM/ODM partners, using trade agreements wisely, and planning inventory more efficiently, brands can reduce their tariff risk and stay competitive in key markets.

In a world of shifting regulations and economic uncertainty, those who plan ahead—and choose the right partners—will lead the way.

👉 Learn more about Salvere Bath OEM/ODM capabilities

and how we manufacture acrylic bathtubs in Vietnam.